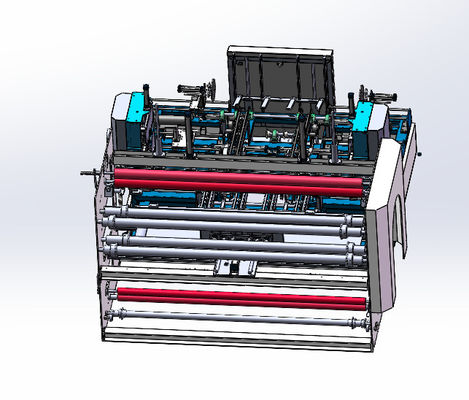

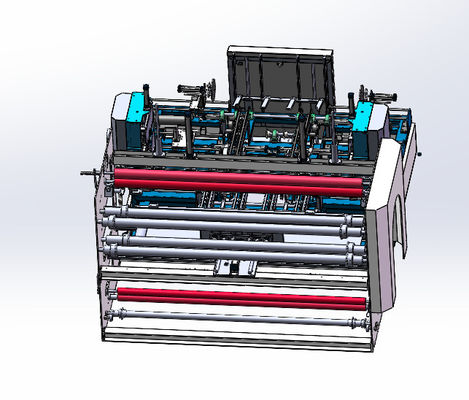

Automatic Textile Roll Packing Machine Pillow Core Wrapping Packing Machine

Introduction of Automatic Textile Roll Packing Machine

The Automatic Fabric Roll Packing Machine offers a seamless, fully automated packaging process. It employs vacuum packaging technology to ensure a secure seal around each fabric roll, safeguarding it from dust, dirt, and potential damage during transportation. Labels, including barcodes, product details, and branding information, are automatically applied for convenient identification and tracking.

Benefits of Automatic Textile Roll Packing Machine

Automatic Fabric Roll Packing Machine stands out with its cutting-edge features that revolutionize the fabric packaging industry. Its fully automated process ensures that the entire packaging workflow is seamlessly executed, requiring only one operator to monitor and oversee the entire operation. This not only maximizes efficiency but also significantly boosts your return on investment (ROI) by minimizing labor costs and maximizing production output.

automatic fabric inspection capability:It employs advanced sensors and imaging technology to meticulously inspect each fabric roll for defects, ensuring that only high-quality rolls are packaged. This ensures customer satisfaction and maintains the brand's reputation for excellence.

The machine incorporates automatic vacuum packaging, which uses a vacuum pump to remove air from the packaging material, creating a tight seal around the fabric roll. This not only protects the fabric from dust and dirt but also prevents it from being crushed or damaged during transportation.

Functional Advantages

The textile roll packing machine specializes in rolling and compressing fluffy items like clothing, blankets, towels, pillows, mattresses, cushions, and pet mats. This machine effectively reduces the overall volume of these items, leading to significant savings in storage and transportation costs. Additionally, it offers flexibility in packaging material, allowing the use of various types of bags such as plastic, non-woven, cloth, woven, and paper waist seals.

Automatic Textile Roll Packing Machine Models and Specifications:

| Model |

CQ-AFR16 |

CQ-AFR19 |

| Fabic Roll Information |

Width |

1000~1600mm |

1000~1950mm |

| Diameter |

100~350mm |

100~500mm |

| Weight |

5~60kg |

5~80kg |

| Capacity |

5~6 rolls/min |

4~5 rolls/min |

| Packaging film |

Material |

LDPE FILM |

LDPE FILM |

| Thickness |

0.03~0.08mm |

0.03~0.08mm |

| Power Source |

AC380V

3Phase

50/60HZ

12.6Kw/h

|

AC380V

3Phase

50/60HZ

14Kw/h

|

| Air Source |

5~7kg/cm² |

5~7kg/cm² |

Special specifications can be customized

Applicable Industries

The textile roll packing machine is suitable for a wide range of industries, including hotels, garment shops, building material stores, manufacturing plants, machinery repair shops, farms, restaurants, home use, retail stores, food shops, printing shops, construction works, energy and mining, food and beverage shops, as well as advertising companies.

FAQ

-

What is the duration of the machine warranty? The machine comes with a one-year warranty, excluding damaged parts.

-

Does the machine undergo testing before delivery? Yes, we provide test videos and photos to our customers before shipping to ensure quality.

-

How do you handle after-sales support? We typically provide guidance through either direct assistance or video tutorials.

-

Is there a minimum order quantity? There is no minimum order quantity or restriction.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!