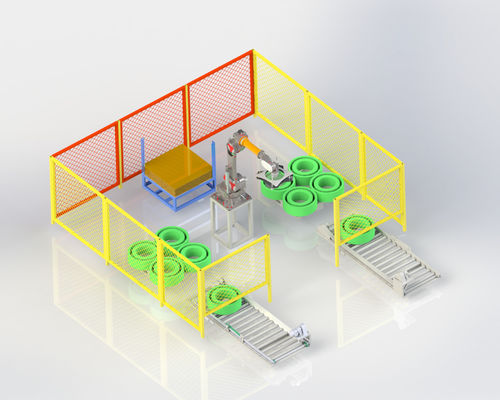

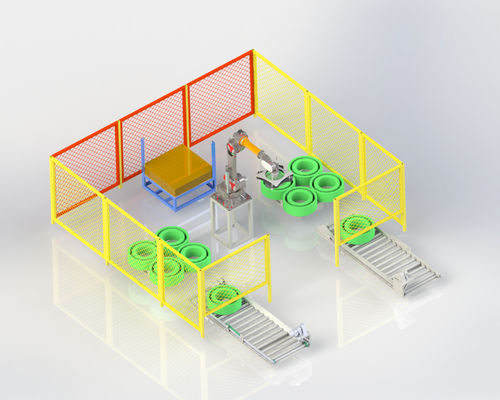

Automated PET strapping winder winding machine with automatic Palletizing System

Palletizing program:

A: Strap OD 600MM, height 150MM, weight 20KG, 1 layer of 4, separated by cardboard, up to 12 layers.

B: Strap O.D. 800MM, height 190MM, weight 75KG, 1 layer of 2, cardboard separated, up to 7 layers.

Robot arm model: JZJ160A-270

Speed: 40 seconds per roll, an automatic palletizing system can match up to 2 sets of one out 8 PET strap production lines.

Cardboard platform dimensions: length 1240mm x width 1240mm x height 1500mm

Positioning conveyor belt size: length 3220mm x width 1170mm x height 680mm

Robot arm base: length 700mm x width 700mm x height 1000mm

After the finished product arrives at the positioning position of the conveyor belt, the robotic arm grabs the finished product onto the pallet until one layer is full. The robotic arm then picks up the cardboard finished product pallet from the cardboard pallet and repeats the action until the finished product pallet is stacked.

CQA800F suitable for one out of six, one out of eight PET strap production line with robotic arm use.

Basic equipment

- Dancer control for controlling a constant strap tension and winding speed, Dual servo motor

- Precise, electronically controlled 2 or 3 point laying with minimal strap bend of the straps

- Pneumatic lamella spreading mandrels for fast bobbin change

- Sleeve magazine

- Bobbin deposit

- Automatic film dispenser

- Two measurement modes: weight and meter

Facts and advantages

- Fully automatic PET strap winder for straps from 9 to 32 mm, with an outer package diameter of 820 mm

- Conveyor system for automatic package transport

- Film wrapping device for automatic package wrapping

- Central input terminal with recipe management

- Fully automatic winding can be achieved with or without paper core

Technical details

| Model |

CQA800F |

| Winding speed |

50 – 250 m/min |

| Maximum pick up speed |

350 m/min |

| Maximum mandrel rotation speed |

500 m/min |

| Strap width |

9~32mm |

| Traverse length |

50~200mm |

| Mandrel diameter |

406mm or customized |

| Maximum package diameter |

820 mm |

The strap winder of the CQA800F was used for winding straps in parallel directly from the extruder.

The systems work independently once the material has been applied manually. They can be integrated into fully automated overall production plant. They wind pet straps with width of 9~32mm depending on configuration.

Once a winding package has reached the desired circumference, it is wrapped with film by the intergrated winder and tipped by the integrated transport system from the winder down to the roller conveyor below. A new winding tube is fed from the magazine at the same time and the next package is wound fully automatically.

The machines were developed for continous operation. The compact design permits use even in confined spaces.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!